Summary

Today on the Reschexpert blog we put two Rescheck heavyweights against each other. Batt insulation is the old insulation in the comparison after being used for nearly a century. Spray foam is the relative new comer in the Rescheck insulation world. It has been used by the military and aviation world to insulate planes since the 1940s, but not nearly as long in residential or commercial housing. The 1970s was when it began being used to insulate homes and more recently in the past 2 decades has it picked up more prominence and popularity.

Jobe Leonard wrote this article for Rescheck.info and the Reschexpert blog. He enjoys testing, installing, and Reschecking both batt insulation and spray foam insulation for others.

Jobe Leonard Rescheck.info

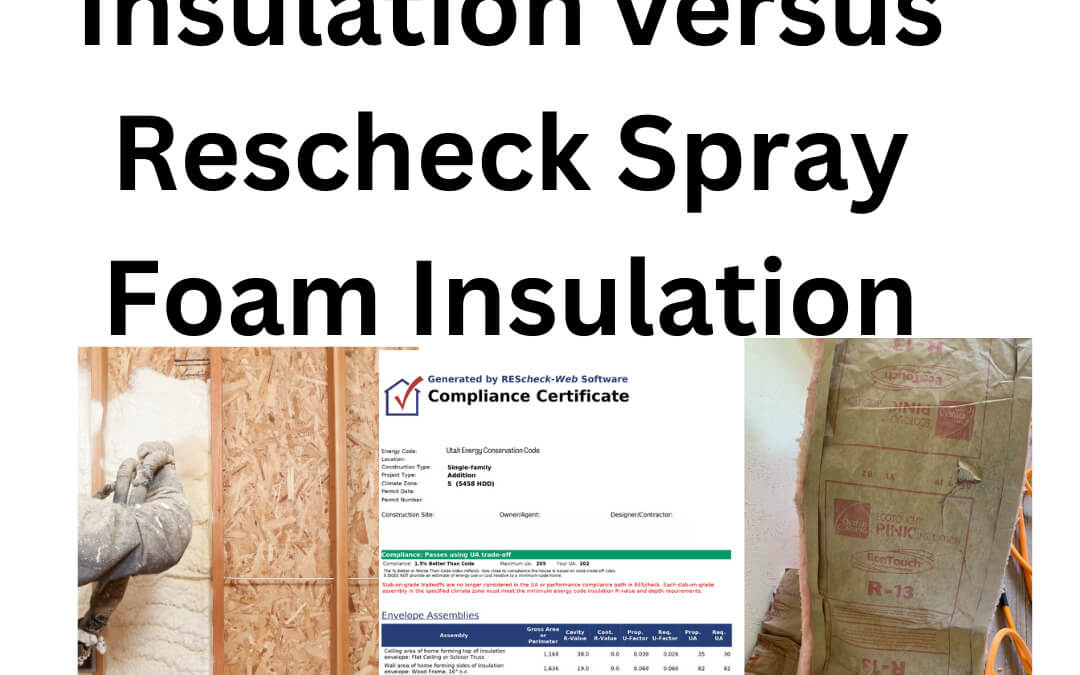

Rescheck Batt Insulation versus Rescheck Spray Foam Insulation

Today on the Reschexpert blog we put two Rescheck heavyweights against each other. Batt insulation is the old insulation in the comparison after being used for nearly a century. Spray foam is the relative new comer in the Rescheck insulation world. It has been used by the military and aviation world to insulate planes since the 1940s, but not nearly as long in residential or commercial housing. The 1970s was when it began being used to insulate homes and more recently in the past 2 decades has it picked up more prominence and popularity.

Let’s look at both types of insulation, batt insulation and spray foam insulation as they pertain to Rescheck.

Batt insulation:

Common makeup: Fiberglass, Wool, Mineral, Cotton, Cellulose

Sizes: 2×4 cavity, 2×6 cavity, 2×10 cavity, 2×12 cavity, 2×14 cavity, various foundation wall larger blanket sizes

Lengths: 4 feet long, 8 feet long, 20+ feet long to cut to length

R Values: Standardized and tested. R 11, R 13, R 19, R 30, R 38, R 49 readily available.

Benefits: Low cost, Easy to install, Fire retardant, Offers some sound proofing, Readily available, Limited settling, Easy to add additional layers, Flexible, easy to remove, cost

Weakness: Itchy, irritates skin and respiratory system during install, seal of ceiling and walls is not overly tight, moisture damage, paper backings.

Do it yourself ease: Can be done with readily available tools.

Spray foam:

Common makeup: Polyisocyanurate, Polyurethane, Polystyrene, Cementious

Sizes: The spray foam is typically applied and sold by the inch. A 2×4 cavity might get a 3.5” application.

Lengths: Spray foam can be applied in any length as it is sprayed into place.

Benefits: Some of the material options have high R value per inch, Can create a good seal, Sound insulation, Longevity, Moisture resistance, Can insulate areas with unconventional sizes fully.

Weakness: Chemical makeups, outgassing, air quality, requires expensive equipment and training to install, non standardized r values across materials, difficult to remove or replace, mold, termite damage, shrinkage over time, cost, air bubbles, non standardized application methods, gaps, improper curing causes issues.

Do it yourself ease: Nearly impossible. Expensive equipment, training, and learning curve make this a type of insulation that is better left to a reputable spray foam insulation company with many positive reviews, longevity in the industry, and a track record of integrity.

Now that we know the competitors let’s look at batt insulation and spray foam insulation as they pertain to Rescheck. For the batt insulation and spray foam insulation and their inputs into Rescheck software like Rescheck Web or Rescheck Desktop it might be hard to believe but they are nearly identical. Both spray foam and batt insulation are measured in R values. These R values are almost always placed into the cavity portion of the Rescheck Web or Rescheck Desktop software. This means they are applied between two studs, rafters, or floor joists. The dimensional framing lumber acts as a break in the insulation therefore it is considered a cavity type insulation and not continuous. For batt insulation or spray foam to be considered a continuous insulation in Rescheck it would need to be applied without the 16” or 24” of stud or dimensional lumber framing. An example of this for batts might be a basement rock wool curtain batt that is not broken up by framing. Spray foam you might have an application where you sprayed a large cavity on a roof system, but it is more rare to be able to use Spray foam as a continuous insulation, although many spray foam salesman might tell you otherwise.

So with the R values of batt insulation and spray foam insulation being identical in the eyes of Rescheck and Rescheck software like Rescheck Web and Rescheck desktop then who is the winner. Due to the many abnormalities seen in spray foam estimates and the non standarized nature of spray foam application and materials the winner of this comparison goes to batt insulation.

Being easier to install, less costly, and having a fully tested and vetted R value printed right on the material makes it the winner, for now. Spray foam falls behind because many of the installers provide unknowing customers with estimates that simply state 3.5” of insulation or 5.5” of insulation. This really means nothing without an attached R value per inch, proof of the installed material, evidence that the actual inches of material are installed, and a thorough inspection that the spray foam was applied correctly.

With a fiberglass batt the insulation and R values are standardized so if your Rescheck, climate zone, and IECC energy code like IECC 2018, IECC 2021, or IECC 2024 require a certain R value you are guaranteed to have that particular R value because it is printed right on the material itself. With Spray foam insulation testing of what is installed to insure that it is what they say it is could cost more than the actual insulation job itself.

In closing I would say if you have a reputable spray foam installer with a proven track record your comparison of batt insulation to spray foam insulation could easily show spray foam as the winner. I do not discourage you from using spray foam on Reschecks. I only encourage you to get a written estimate from any spray foam provider that tells you the type of material being installed, the inches that it will be installed to, the R value per inch, the total R value of the application, and what type of installation certifications and training that the installers have. Then make sure the the people listed on the training are the ones who actually show up on spray foam installation day to install your spray foam installation to the Rescheck spray foam specifications.

Overall, if you need a Rescheck created for either spray foam or batt insulation we can do it. We can also do a mix of the two materials. Total R value, pdf plans, jobsite address, and square footage are important. Email that information to service@rescheck.info and we will get you taken care of.

Free Spray Foam Rescheck vs Free Batt Insulation Rescheck PDF